Every day modern technologies are becoming more flexible, both literally and figuratively. Korean LG has already announced its plans to introduce flexible smartphones and even presented a suitable display, almost as good as the technical characteristics classic panels. Revolutionary, incredibly practical and flexible batteries have also exist. And now they are tightened and microprocessor technology.

Scientists have long wondered about the rejection of classical silicon as the basis of microprocessors. There were even some results achieved through the use of different materials, but they all have the same favorable properties as silicon. Now Dutch scientists have been able to solve the problem and flexibility while retaining all the advantages of the silicon structure.

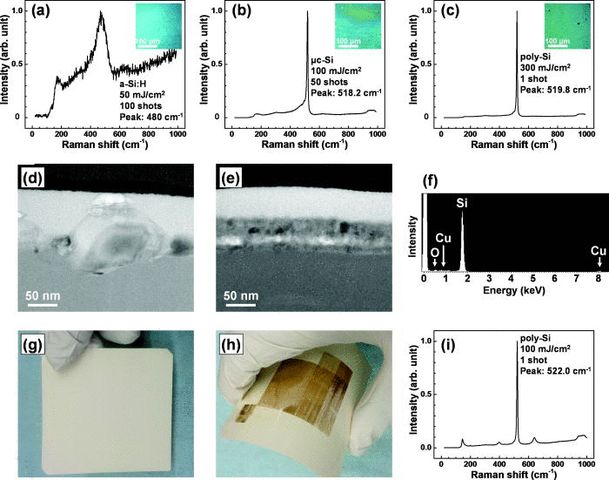

Their method allows the silicon directly on the silicon substrate of liquid ink using a single laser pulse in polycrystalline form used in the respective circuits. The principle of this type of printing on substrates has been around for a long time, but previously it required the temperature reaches 350 degrees Celsius – not any flexible surface was capable to withstand this temperature. The new approach does not require burning and immediately turns the liquid silicon in the polysilicon.

How to tell the scientists, the process was very simple: they are just covered with liquid paper polysilanes or smeared it like butter on bread, on the substrate in the oxygen-free environment and allowed an excimer laser pulse (used in laser vision correction and semiconductor manufacturing). The duration of the pulse is a few tens of nanoseconds, allowing did not affect the paper in the process.

In subsequent tests, scientists have determined that thin film transistors produced by this method have a conductivity comparable with classical polysilicon conductors.

The most important achievement is that such structures are energy efficient, flexible and incredibly cheap. In further studies, scientists not only want to improve the production process itself, but also include additional, non-silicon layers, which will also extend the scope of Technology (now the basis for predicting its flexible wearable electronics). The project manager said that their decision to allow in the future to produce not only a flexible, deformable electronics, but even to make it edible.

BREAKTHROUGH IN MICROPROCESSOR: flexible electronics on the approach

No comments:

Post a Comment